Traceability Solutions

Traceability is the capability to trace something at any point of time to verify the history, location, or application of anproduct by means of documented recorded identification. Increasing in product categories leads to complexity in manufacturing process. In many aspects that it may become necessary for manufacturers to track and trace the origins of products. Traceability is very important in any kind of manufacturing facility as it provides the ability to quickly recall the products and match the necessary standby parts. Production traceability is a necessary thing for today’s industrial business to reduce the risk factors and stay competitive. Track and trace information need to be maintained highly regulated industries such as medical, defense and aerospace, automobile, food and beverage etc. Now a days traceability plays a vital tool for all manufacturers to have better control over product and process quality to respond to customer demands.

When things goes wrong, it is the one of the most expensive, confusing and waste of time and material in manufacturing business. To do the things properly traceability, in this new age of digital manufacturing, has never been so inexpensive, and with the recently increasing the business efficiency in all aspects.

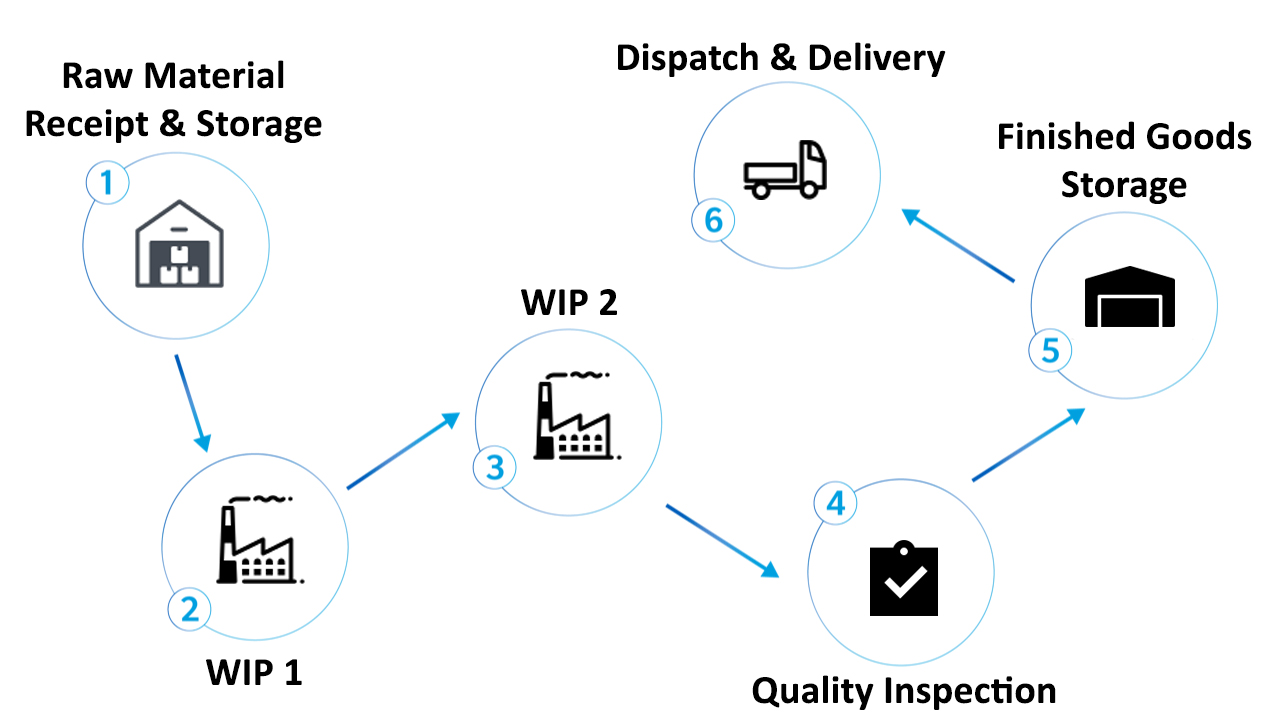

We at Ess-Matrix, has industrial domain experts to address your all traceability solution with information technology. Initial step in process of traceability application is to capture the incoming material from the supplier with the PO number, Lot Number, serial number etc. Our traceability solution considers from the supplier material to end product till delivers to customer.

Benefits of our Traceability Solution:

- Get Visibility of material across warehouse, WIP and Finished goods inventory

- Application enables with bidirectional traceability both forward and backward traceability of materials.

- Mechanism to comply with local and international policies and regulations

- Reducing likelihood of recording errors.

- Allowing automatic reconciliation of batches and volumes available.

- Reducing the risk of illegal or non-compliant material entering the supply chains.

- The inbuilt validations and balances in the software ensure that the succeeding step can be carried out only if the preceding steps were successfully complied with.

- Products are physically marked during manufacturing and then monitored from this instance and thereafter

- Vision inspection for complete product integrity

- Delivers accurate and timely reports and documents to meet the industry regulations and quality audits and Recall & Analysis

- Provision to Track and troubleshooting supplier performance and quality problems

Get a free Traceability Software Demo