Material Resource Planning Software

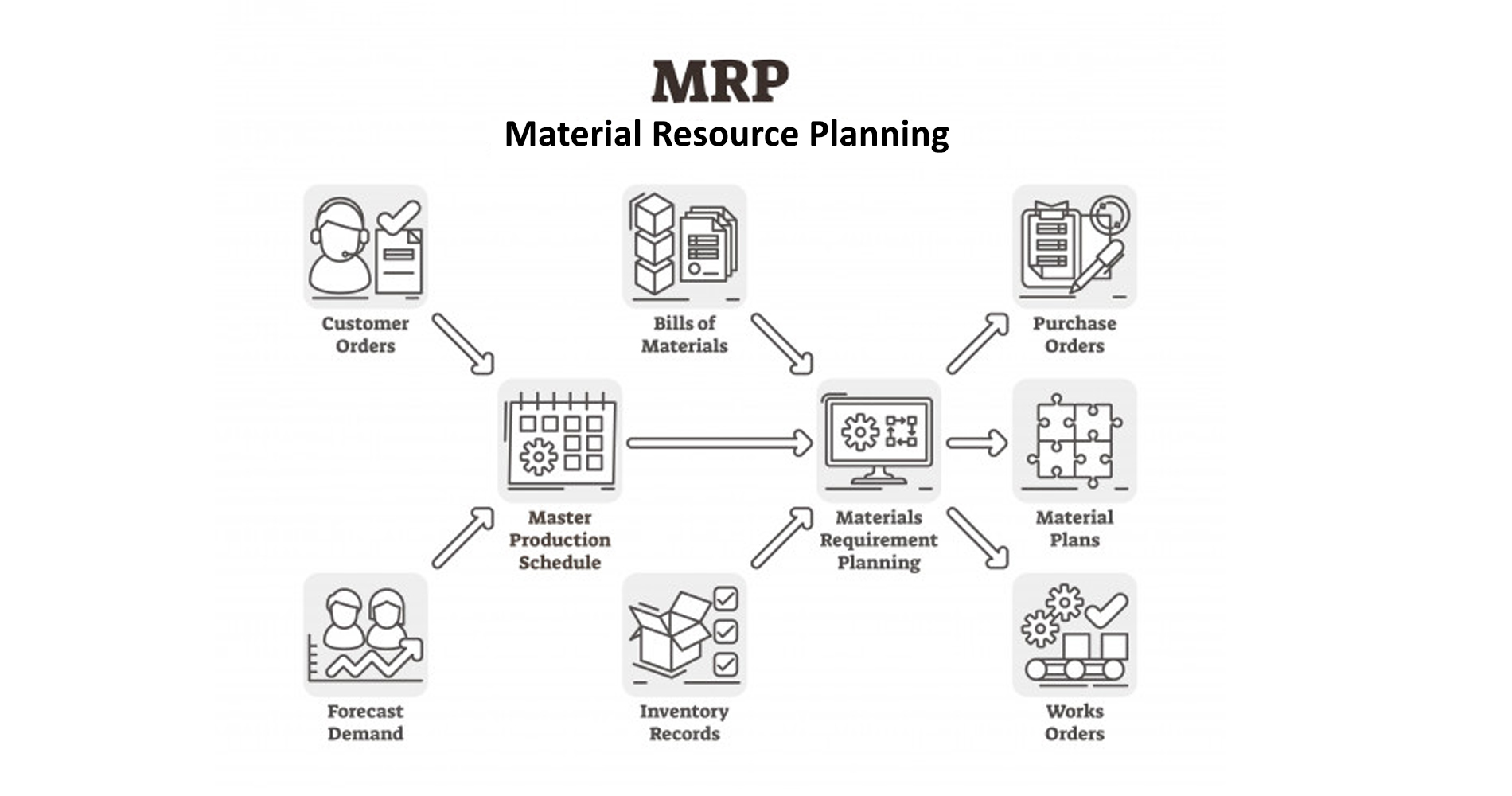

Essmatrix is creating path for today’s manufacturers to streamline business processes and overcome the challenges of production by breaking down hurdles to growth. With Essmatrix MRP, a robust manufacturing execution System, manufacturers can effectively handle customer demand and respond to evolving markets. Our software can easily share data seamlessly from Inventory and Purchasing to ensure that the materials you require to manufacture your goods are available and can be utilized to keep your business running.It often covers the period from when a product is made, raw materials qualified and purchased, resources are located, to when production is actually planned. After this, manufacturing execution systems then take over.MRP application holds the capability of evaluating to planning, buying to transportation, process for production keeps frameworks to give a diagram of the whole business. This can offer the data to analyze for executives at all the levels for planning and making the decisions.

Businesses typically use MRP software to aggregate data to help improve operations across the board. The most common usage for this software is in logistics, but businesses also use it to formulate future plans for pricing possibilities, hiring decisions, and marginal productivity. To do this the software typically aggregates data from employees and accounting books as well as other areas of particular interest for business evaluation.

A good MRP software solution can turn a good business into a great business, identifying wasted time and costs and helping you turn work into cash more quickly than ever before. Businesses can also make better use of employees and other resources, creating tighter shifts and scheduling less downtime for equipment.

Features and benefits of MRP Software:

- Better inventory control and optimizes inventory levels so business should not holding component parts unnecessarily

- Effective materials traceability with batch and serial numbers.

- Guides you to create master production plan and generates automatic BOM

- Production Floor Data Capturing system with Bar-coding, RFID etc.

- Automates your purchase schedules with inventory re-ordering rule.

- System have the capability to integrate with any kindly machine interfaces

- Generates material requirements through every level of the product structure.

- Allows master schedule firm planned orders to be automatically created based on the master schedule for an item, when used with the MRP

- Single instance global MRP software, web based application available in both on-premised and cloud.

- Provision to manage subcontracting as well as services/tasks.

- Provision to manage your test quality certificates as well.

- Optimize your purchase’s, production, sales and logistics activities.

- Generates pick list for orders and generates Sales invoices and shipping documents according to delivery route

- Real-time production and inventory reporting to allow early detection and proactive responses to problems

- Dynamic reports for your materials, production data and sales activities.

- Provision to maintain organizational data for all your customers, vendors, items, product route, bill-of-material, and work centers etc.

- Default API’s will be provided to integrate with any kind of finance module.